Planning an event involves careful consideration of various elements, including entertainment, logistics, and promotional activities. Incorporating live screen printing into your event can add a unique and interactive dimension, allowing attendees to create personalized apparel and merchandise on-site.

To execute this successfully, understanding the essential live screen printing equipment is crucial. Find out more in the following article.

What is Live Screen Printing?

Live screen printing brings the experience of customizable gear and swag directly to the crowd. Guests are engaged to make their very own custom garment in minutes with each individual bringing home a personalized gift, plus empowered by the experience and a positive memory anchored to the brand or client.

Now, let’s explore the key components necessary for setting up a live screen printing station at your event.

Screen Frames: The Foundation of Screen Printing

Screen frames are the structural backbone of the screen printing process. Typically constructed from metal or wood, these frames are precisely stretched with fine mesh fabric, usually polyester. The mesh screens serve as the stencil carriers, allowing ink to pass through onto the printing surface.

Mesh Screens: The Heart of Screen Printing

Mesh screens are essential components of screen printing, serving as the critical element in transferring designs onto materials. Traditionally made from silk thread, modern screens today mainly utilize polyester fabrics for durability and affordability. These screens, coated in emulsion and exposed to light, act as stencils during the printing process.

Squeegee: Pushing Ink with Precision

The squeegee is a vital tool in the screen printing arsenal, responsible for evenly pushing ink through the mesh screen onto the material being printed.

Equipped with a rubber blade and handle, the firmness of the squeegee blade depends on the intricacy of the design. Firmer blades are ideal for detailed designs, while softer blades are suitable for less intricate prints or fabric applications.

Inks: Adding Creativity to Printing

Inks are the creative soul of screen printing, offering a variety of effects on the final product. From glittery to texturized, or even puff inks that create raised surfaces, there are numerous options to choose from. Selecting the right ink type depends on the desired visual and tactile elements, as well as the material being printed on.

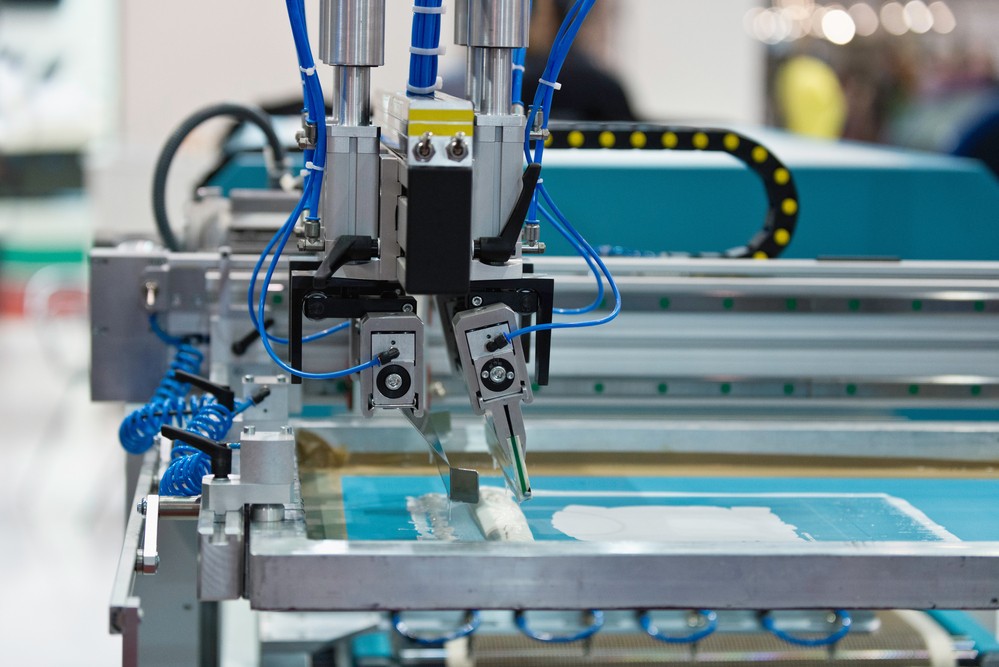

Screen Printing Press: Efficiency in Printing

While screen printing can be done manually, many opt for a screen printing press to streamline the process. These presses secure the screen and allow for swift material changes, making printing more efficient. Manual, semi-automatic, and automatic presses are available, with the choice often based on the volume of printing required.

Washing Station: Maintaining Screen Quality

After printing, screens must be carefully cleaned to get rid of all emulsion traces. Correct cleaning methods make sure that screens remain in excellent condition for future use. A washing station equipped with the necessary tools and solutions is essential for maintaining screen quality and longevity.

Incorporating live screen printing equipment into your event can elevate the attendee experience and create memorable moments. By understanding the essential equipment and how to utilize it effectively, event organizers can harness the power of live screen printing to engage audiences and leave a lasting impression.

Get Started Today

You don’t have to worry about getting all the live screen printing equipment when you hire the pros. Whether you’re hosting a corporate event, music festival, or product launch, our team is here to ensure your attendees leave with personalized, one-of-a-kind merchandise they’ll cherish. Get in touch now to discuss your event needs and let’s make magic together!